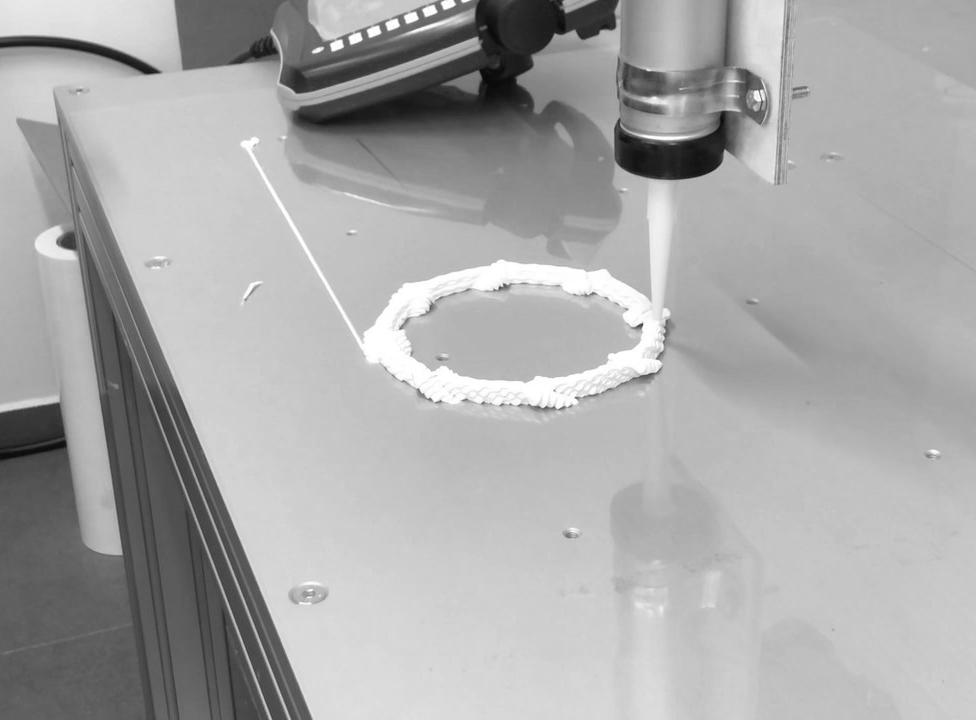

The production process included a number of experiments. In the experiments we investigated the different capabilities of the robotic arm, the different heads that can be connected to the arm and the material with which they work. One of the experiments involved the production of a structure by three-dimensional printing. The printer head contains the construction material which is a Synthetic Polymers. During the experiment, the synthetic polymer came out with the help of air pressure. The structure is created by stacking layers of synthetic polymer in rounds. Every eighth circle, the head makes a movement outside and then back inside. This movement is repetitive with an offset for every layer.

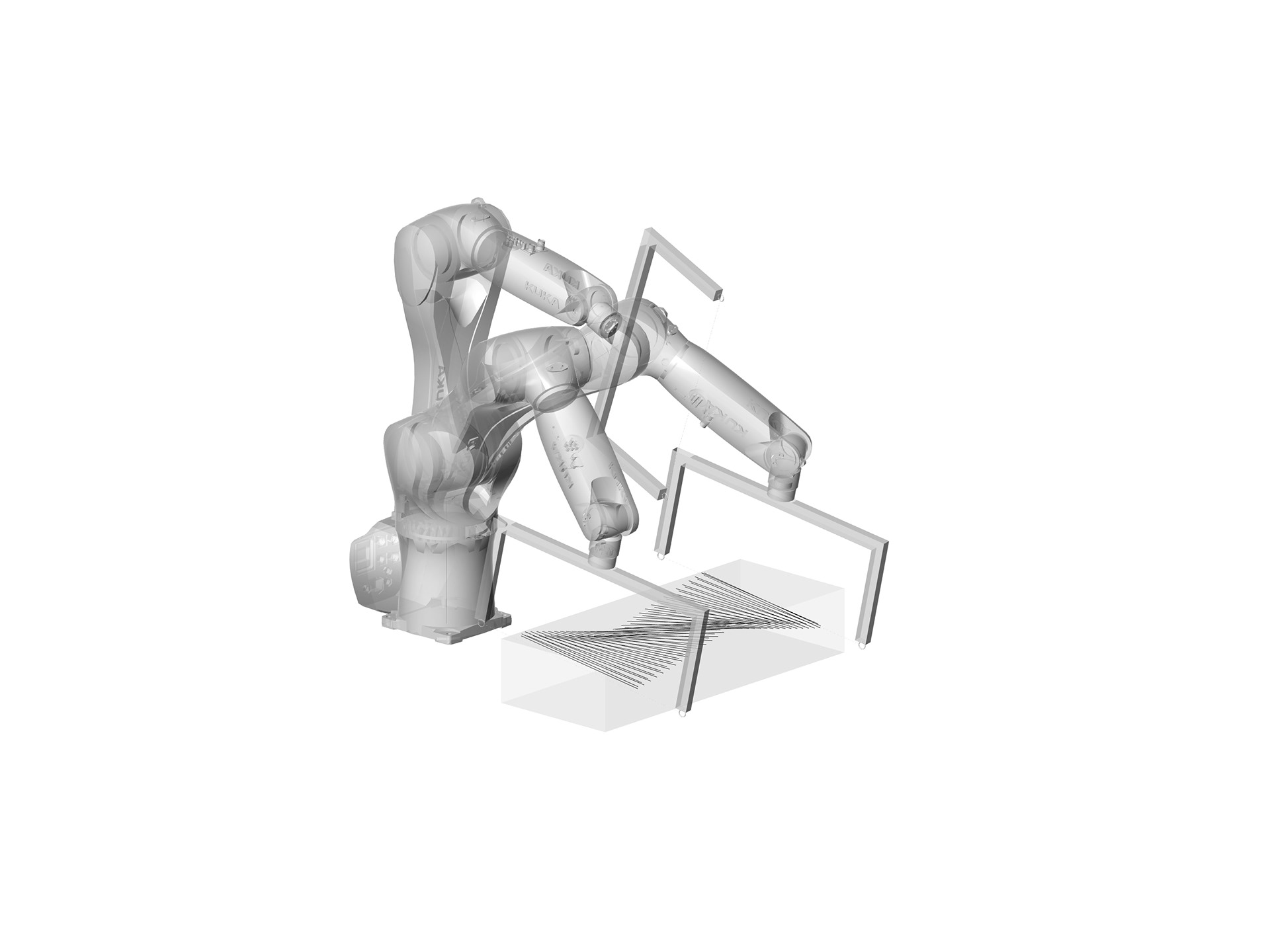

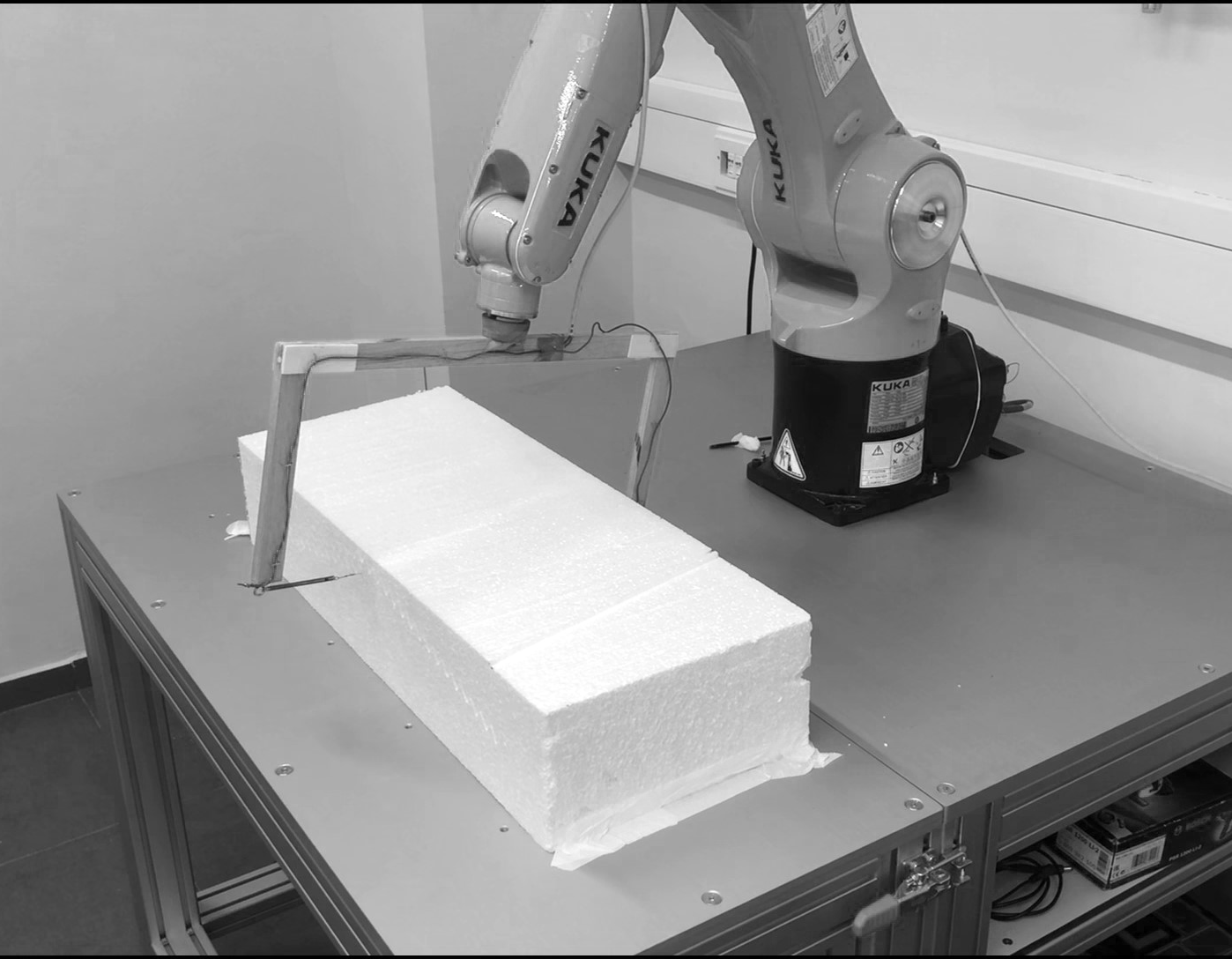

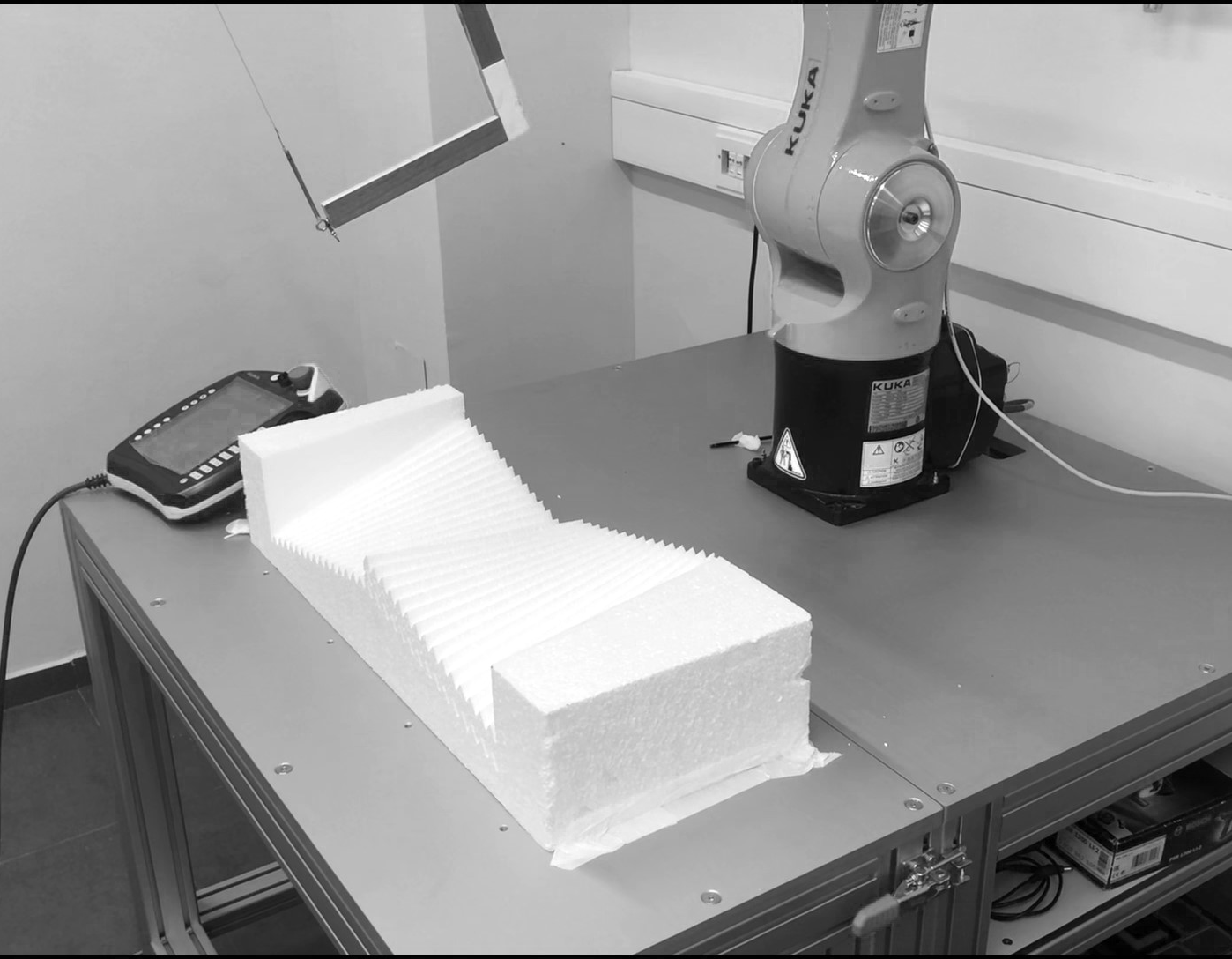

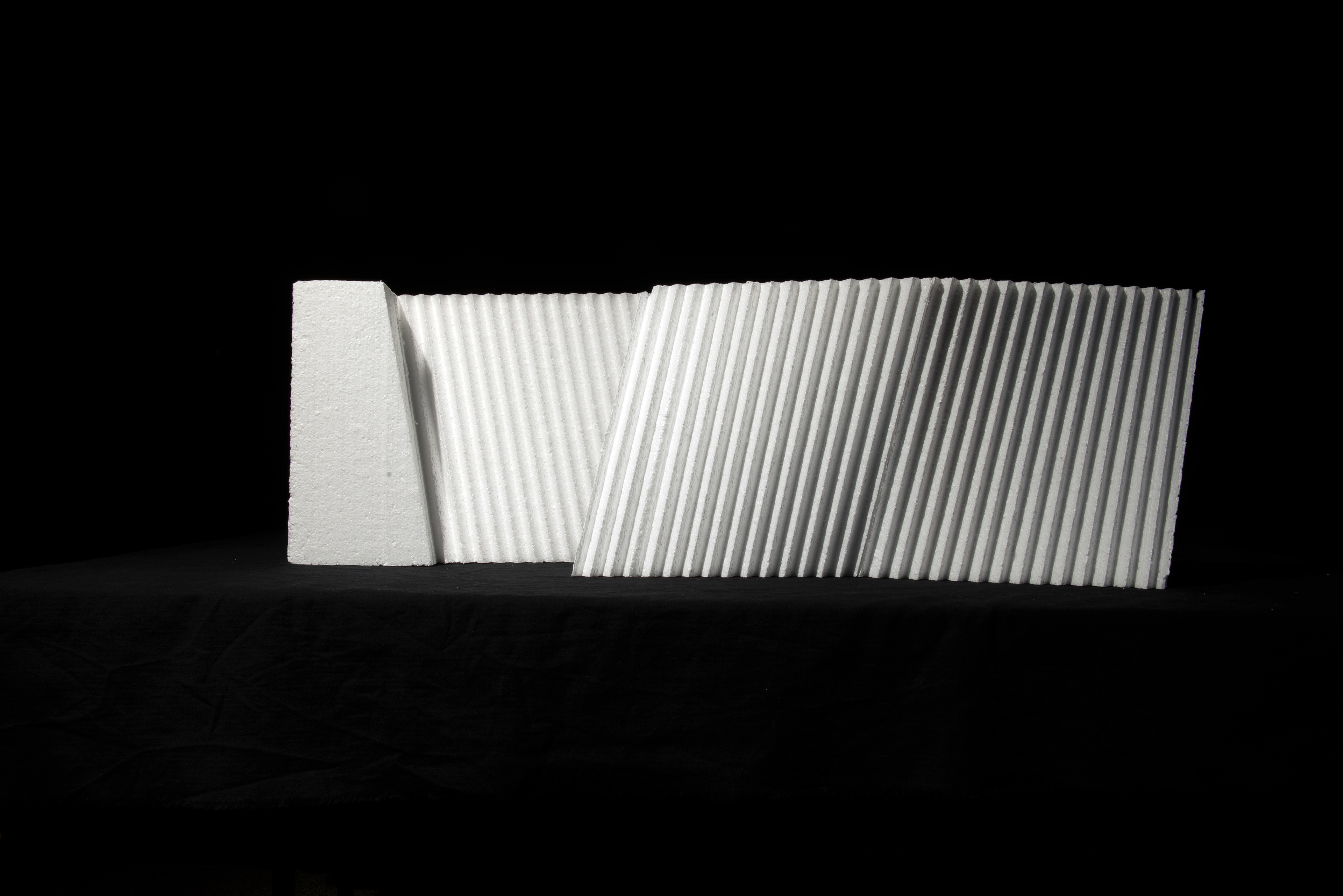

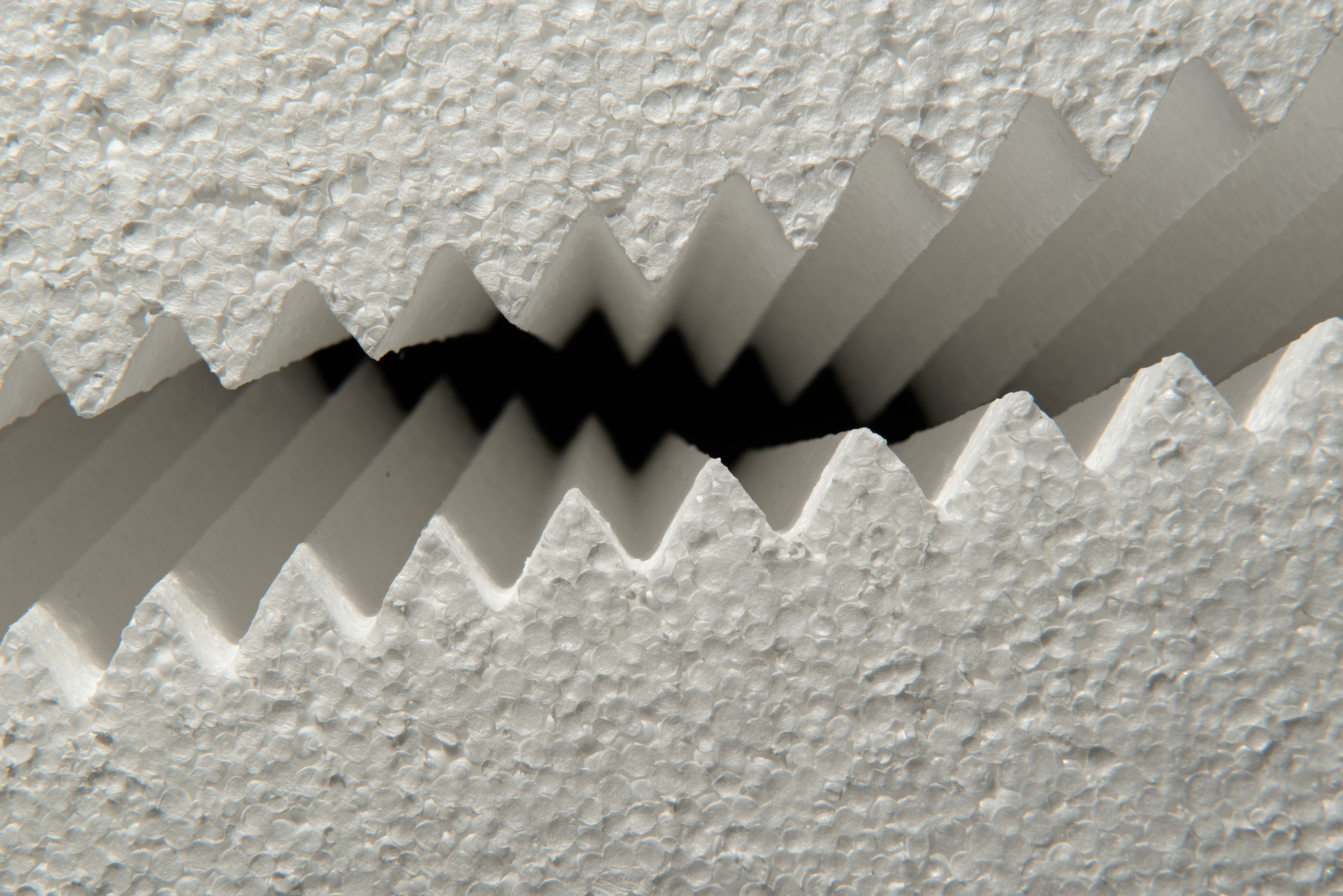

Another experiment dealt with cutting polystyrene with a hot wire cutter. The aim of the cutting was to create a mold with a texture allowing for casting material inside. The head attached to the robot is made of a wooden frame, the hot wire is stretched inside the frame. In order to produce the mold, we created a curved surface, and on this surface, we created the texture. In order to create a volume inside the polystyrene, we duplicated the track with an offset. In the end of the process, we casted plaster into the mold.